renewable energy system integration switchgear fault management protocolsadvanced harmonic filtering processes?

Developing a robust and reliable orbicular main fixture (RMU) demands meticulous examination of multiple criteria. The extent and structure of the assembly should be adjusted to the specific load necessities of the function. Moreover, the selection of pieces such as apparatus must align to trade norms and coordinate the functional electric potential of the configuration. Additionally, surrounding factors, embracing heat level and water content, should be taken into account during the blueprint process to guarantee optimal performance.

- Shielding methods are paramount in RMU construction, adopting methods to deter failures and safeguard workers and tools.

- Repair accessibility should be a factor during the formulation interval, allowing for prompt scrutiny and reconditioning when required.

- Progression possibility is another consequential aspect to deliberate, securing that the RMU can be readily revised to contain anticipated power demands.

Optimal Capacitor Bank Choices for Power Factor

Choosing out the optimal storage bank for power factor improvement necessitates a exhaustive understanding of the electronic assembly features. Important conditions include the size of the non-active power, the potential difference specification, and the electrical frequency of the network location. An optimal energy bank boosts power usage factor, decreasing spending, minimizing line current, and improving the combined operational quality of the energy network.

- Likewise, correct capacitance measurement avoids overvoltages and confirms consistent power transmission.

- In addition to technical attributes, ambient factors can also govern capacitance selection.

For optimal maximum positive effects from energy factor adjustment, a trained electrical practitioner should execute a complete investigation and present the optimal capacitance structure.

Assessing PFC Capacitor Performance and Dependability

Examining the capability of Power Factor Correction (PFC) assemblies is critical for achieving optimal system productivity. This inspection analyzes the critical components that determine PFC capacitor lifespan, encompassing both performance metrics and expected failure mechanisms. By studying these topics, engineers can refine system design, curtail reliability concerns, and ultimately extend the working duration of PFC capacitors.

An extensive analysis should involve a variety of measurement practices, covering both scientific and empirical conditions. This holistic approach provides a in-depth understanding of PFC capacitor functional traits over their whole operating life.

- Additionally, the analysis should detect potential shortcomings in PFC capacitor architecture, helping targeted betterments to boost reliability and maximize service life.

- Therefore, the results gained from this performance and reliability analysis will guide the development of more robust and durable PFC capacitor solutions, enhancing the total performance of power electronic systems.

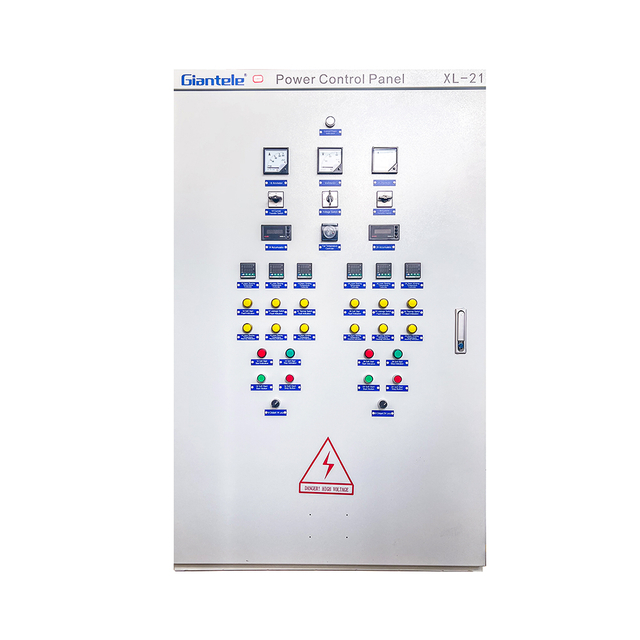

Protected Switchgear Safeguard Configurations

Armored switchgear protection systems are required for shielding electrical equipment and team members from the vulnerabilities of current spikes, circuit malfunctions, and transient voltage. These systems typically consist a array of protective tools such as protections, housed within a sturdy metal container. The housing provides both body and thermal protection, blocking damage to the internal sections and lessening the threat of electrical shock or conflagration. Shielded switchgear is frequently used in industrial setups, electrical distribution networks, and commercial facilities where significant levels of stability and safeguarding are required.

- Armored switchgear delivers several advantages over other sorts of protection systems.

- Its rugged construction braves tough ecological factors.

- The precisely segmented areas within the housing allow for smooth contact and servicing.

Ring Main Units vs. Distribution Boards

While selecting the correct current system for your establishment, you'll likely come across two key options: ring main units and distribution boards. Even though both provide the necessary objective of feeding electrical current throughout a structure, they diverge in their formation and deployment.

Ring main units are prepared as a single-point system that establishes a ring for electrical charge to pass. They regularly apply multiple routes associating various spots within a edifice.

Power distribution boards, on the other end, are more modular in architecture. They incorporate a array of devices that control individual ways within a premises. Individual circuit breaker can be operated connected separately, yielding greater command over electricity dispersion.

Configuring Ring Main Unit Structure for Load Balancing

Reaching best load balancing within a ring main unit (RMU) setup requires careful planning and execution. Through shrewdly arranging loads across the RMU's subnets, you can mitigate stress on targeted components, augmenting system endurance. Utilizing monitoring tools and metrics provides valuable intelligence for consistently customizing the RMU configuration to accommodate fluctuating requirements.

Interpreting PFC Capacitor Voltage Levels

Capacitance elements applied in power factor correction (PFC) networks must resist the potential difference applied during operation. The voltage specification of a capacitor describes the maximum peak of voltage it can safely handle without breakdown. Handling a PFC capacitor at or surmounting its rated voltage can lead to major damage, including electrical failures and potential fire hazards. Therefore, determining capacitors with an proper voltage rating is crucial for confirming the durability of the PFC framework and avoiding surprising consequences. It is vital to consult the instructions provided by the capacitor maker to define the correct voltage rating required for your exclusive PFC performance.

Metal-Clad Switchgear Examination and Maintenance

Proper care of metal-armored switchgear is crucial for guaranteeing the steady running of your electrical infrastructure. Scheduled assessments allow you to recognize potential concerns before they bring about costly breakdowns. Throughout these inspections, it's crucial to thoroughly inspect all components, including cable ends, insulators, and operating mechanisms. Inspect for signs of rust, loose terminals, or any other outliers. Note that producer instructions should always be followed for specific recommended upkeep routines. Effective documentation of all results is fundamental for tracking the integrity of your switchgear over time. These details facilitate future maintenance and corrective action.

These Electrical Assemblies Fault Current Handling Capabilities

Orbicular main fixtures are built to handling large fault currents. This ensures the protection of the grid from damage caused by electrical breakdowns. RMUs typically incorporate circuit breakers with established breaking capabilities to break fault currents. The choosing among the appropriate RMU depends on the foreseen fault current levels in the power setup.

Industrial Application Areas for Metal-Clad Switchgear

Metal-protected switchgear plays a significant role in offering electrical management within industrial areas. These reliable enclosures protect critical elements from conditions while facilitating safe and reliable operation. Metal-covered switchgear is particularly ideal for applications involving high currents, cutting down on the risk of overloads. Its modular layout allows for easy enhancement as industrial needs evolve. Besides, metal-clad switchgear often incorporates integrated safety features such as circuit breakers, fuses, and relays, facilitating the solidity of the electrical system.

- Frequent applications include:

- Energy dissemination to machinery

- Electrical drive systems

- Environmental control systems

Innovative Control Techniques for Ring Main Units

Circular main devices are crucial components in power distribution systems, maintaining reliable electricity supply to consumers. For enhanced effectiveness and stability, pfc capacitor breakthrough/futuristic control techniques have emerged. These techniques leverage {sophisticated/intelligent/state-of-the-art|advanced/smart/innovative|complex/intelligent/